RBC Lubron Bearing Systems

Contact Us

Send us a message

Note: Messages will be sent to RBC Lubron Bearing Systems only

About RBC Lubron Bearing Systems

Lubron designs and custom manufactures self-lubricating bearings for demanding applications and tough operating conditions. Our products are used in some of the largest projects and most critical applications on the planet, including: power generation (wind power, hydroelectric, nuclear), bridges, buildings, subsea oil production, missile defense systems, large construction cranes, and earthquake seismic isolation for building and skyscrapers.

Lubron designs and custom manufactures self-lubricating bearings for demanding applications and tough operating conditions. Our products are used in some of the largest projects and most critical applications on the planet, including: power generation (wind power, hydroelectric, nuclear), bridges, buildings, subsea oil production, missile defense systems, large construction cranes, and earthquake seismic isolation for building and skyscrapers.

MANUFACTURING

Our manufacturing facilities are modern, flexible and complete, capable of complex tasks with precision accuracy. Our diverse design and manufacturing skills combine to assure consistent quality and reliable performance. All welding is performed in accordance with AWS D1.1, AWS D1.5 and AWS D1.6.

QUALITY ASSURANCE

Our bearings are manufactured and inspected in strict accordance with the requirements of ISO9002. Every phase of manufacturing, from procurement to final inspection, is closely monitored by our Quality Control personnel. Every operation is planned, performed, checked and certified in writing to ensure that all materials and workmanship meet or exceed the requirements of the project drawings and specifications. non-destructive testing (NDT) is performed as required by ASTM certified independent testing laboratories. In-process and final inspection is routinely performed by outside inspection agencies including ABS, Lloyd’s and DNV.

TESTING & DEVELOPMENT

Testing is performed in full compliance with project drawings and specifications. Prototype and full scale proof testing can be performed in-house or by independent testing laboratories. We are able to proof test bearings in-house up to 4.5 million pounds of vertical load. In-house equipment includes hydraulic presses capable of sliding and rotational movement.

ENGINEERING SERVICES

We offer a variety of engineering services from the selection of bearing materials to in-house testing of bearing assemblies to simulate load, movement, velocity, temperature and other environmental conditions present during the actual operation of the bearings. Design, prototype testing, solid model/CAD drawing preparation, consulting, and on-site engineering services are available upon request.

EMERGENCY SERVICES

Our technical team provides quick turn-around for short deliveries and emergency breakdowns. We have an advantage over our competition with the ability to expedite orders on demand.

Please visit the RBC Lubron Bearing System website: www.rbclubron.com

Products

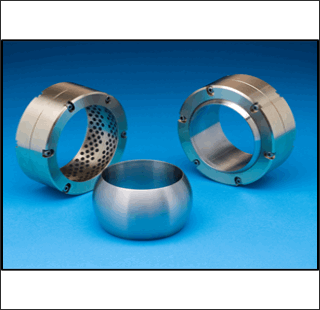

AQ Spherical Plain Bearings

LUBRON® AQ maintenance-free spherical plain bearings are widely used in underwater applications where conditions are often severe and external lubrication is impractical.

Options

LUBRON AQ30 SPB’s (Extreme Operating Conditions)

LUBRON AQ100 SPB’s (Low Coefficient of Friction & Long Service Life)

Features

- Wide selection of corrosion-resistant bronze & stainless steel alloys

- Graphite-free PTFE solid lubricant

- Axial, radial & load slot spherical bearing configurations

- Standard & custom bearings available in both inch & metric sizes

- Hydro Dam Gates & Flood Barriers

- Offshore Oil & Gas Fixed & Floating Platforms

- Marine Mooring Terminals

- Drill Ship & Derrick Barge Cranes

- Hydraulic Cylinders

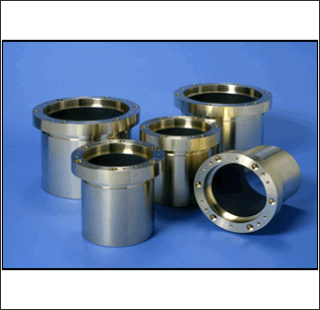

AQ Bushing

LUBRON AQ maintenance-free bushings are widely used in underwater applications where conditions are often severe and external lubrication is impractical.

Options

LUBRON AQ30 Bushings (Extreme Operating Conditions)

LUBRON AQ100 Bushings (Low Coefficient of Friction & Long Service Life)

Features

- Wide selection of corrosion-resistant bronze bearing alloys

- Graphite-free PTFE solid lubricant

- Standard & custom bushings available in both inch & metric sizes

- Hydro Dam Gates, Flood & Tidal Barriers

- Offshore Fixed & Floating Oil & Gas Platforms

- Marine Mooring Terminals

- Drill Ship & Derrick Barge Cranes

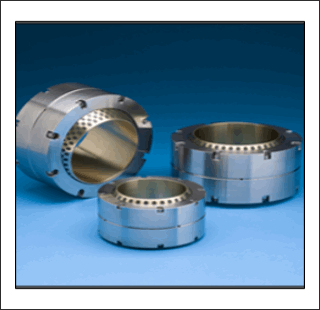

TF Spherical Plain Bearings

LUBRON TF maintenance-free spherical plain bearings are widely used in demanding applications where conditions are often severe and external lubrication is impractical.

Options

LUBRON TF Spherical Plain Bearings

LUBRON TF Track Roller Spherical Bearings

LUBRON TF Slot Loader Bearings

LUBRON TF-HTFE Spherical Bearings (High Temperature)

Features

- Wide selection of corrosion-resistant bronze & stainless steel alloys

- Axial, radial & load slot configurations

- Standard & custom bearings available in both inch & metric sizes

- Seals are available for added protection in very harsh environments

Applications

- Highway, Railway & Pedestrian Bridges

- Heavy Moveable Structures (Bascule Bridges)

- Buildings, Stadiums & Arenas

- Aerospace & Defense (Rocket & Missile Launching, Aircraft Landing)

- Hydro Dam Gates & Flood Barriers

- Hydraulic Cylinders

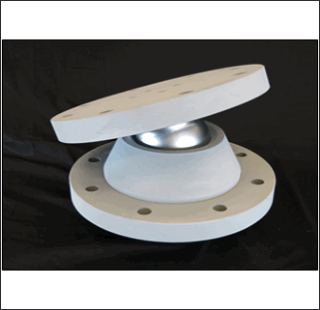

TF Spherical Bearings

LUBRON TF heavy-load multi-rotational (HLMR) spherical bearings have been performing flawlessly in a variety of rigorous structural application for more than 30 years.

Options

LUBRON TF Spherical Bearings (Sliding, Rotation & Angular Misalignment)

LUBRON TF-THE Spherical Bearings ( Higher Speed & High Temperature)

Features

- Advanced & reliable design, heavy load capability and high rotational capacity

- In-house testing capability and exceptional engineering support

Applications

- Bridges (Highway, Railway & Pedestrian)

- Sports Arenas, Convention Centers & Airports

- Skyscrapers – Tuned Mass Dampers

- Seismic Base Isolation

Fiberglide® Coiled Journal Bearings

Fiberglide® coiled journal bearings feature the highest load capacity maintenance-free bearings in the Industry.

Features

- Dynamic load carrying capabilities up to 20,000 psi

- High resistance to fatigue under shock loads

- Maintenance free - No lubrication required

- Lead and mercury free

- Low coefficient of friction

Applications

- Material handling equipment

- Aerial work platforms (scissors and boom lifts)

- Truck liftgates

- Agricultural and construction equipment

- Heavy duty suspension systems

- Recreational vehicle transmissions and suspensions

- Valves for oil & gas pipelines and industrial uses

- Hydraulic cylinders

- Pivot points and linkages

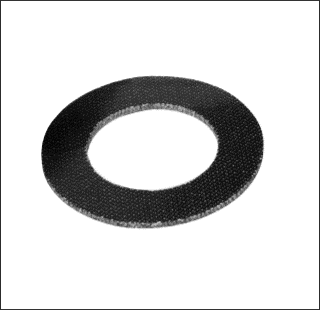

Fiberglide® Thrust Washers

Fiberglide® thrust washers offer Industry leading maintenance-free performance in high load applications. They are available with both metallic and non-metallic backing material supporting the Fiberglide® liner system.

Features

- Dynamic load carrying capabilities up to 20,000 psi

- Maintenance free - No lubrication required

- Lead and mercury free

Applications

- Material handling equipment

- Aerial work platforms (scissors and boom lifts)

- Agricultural and construction equipment

- Heavy duty suspension systems

- Valves for oil & gas pipelines and industrial uses

- Pivot points and linkages

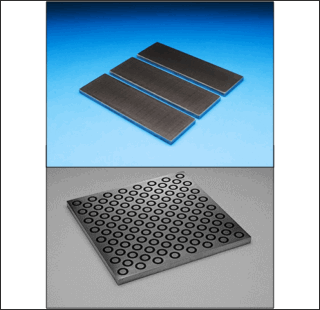

Expansion Plates

LUBRON expansion bearing plates are available in a variety of graphite and PTFE solid lubricants and base materials, including high strength bronze alloys, Meehanite®, carbon and stainless steels. LUBRON expansion plates are maintenance-free and have been in service for 60 years.

Options

LUBRON SL30 Expansion Plates (Infrastructure & Industrial Applications)

LUBRON SL40 Expansion Plates (High Temperature)

LUBRON TF Expansion Plates (High Load & Low Coefficient of Friction)

LUBRON TF-HTFE Expansion Plates (Higher Speed & High Temperature)

Type

- Flat, Radial & Spherical Shapes, Lubricated on one or both sides

- Industrial

- Infrastructure

- Nuclear Power

- Aerospace & Defense

- Fertilizer Plants

Meehanite® is a registered trademark of Meehanite Worldwide Corporation of Sparta, New Jersey

AE40 Nuclear

LUBRON AE40 maintenance-free bearings have been widely used in nuclear power generation since 1971. Capable of long-term exposure to high levels of radiation and high temperatures, LUBRON AE40 solid lubricant is employed to provide long and reliable service life.

Features

- Fifty years of service in critical and non-critical nuclear power applications

- Available in bushings, plates, spherical plain bearings and spherical bearing assemblies

- Steam Generator Upper Lateral Snubber Supports

- Steam Generator Base Supports

- Reactor Vessel & Pressurizer Supports

- Core Makeup Tank Supports

- Reactor Vessel Load Limiters

- Reactor Coolant Pump Supports

- Emergency Cooling Intake System Supports

HX HydroPower Specials

LUBRON HX bearings are constructed of a proprietary machinable liner system containing a homogenous mixture of solid lubricants in a specially designed resin system that is bonded to corrosion-resistant bearing materials suitable for long-term submersion in water.

LUBRON HX bearings provide dependable performance and long term service life, require no supplemental lubrication, and are completely maintenance-free. LUBRON HX bearings offer maximum resistance to wear under the harshest operating conditions.

Features

- LUBRON HX bearings have been tested at Powertech Labs per US Army Corps of Engineers (USACE) (CERL TR #99/104) as well as similar testing performed in-house.

- LUBRON HX exceeded USACE required performance for both wet and dry test programs.

- LUBRON HX bearings exhibited nearly zero wear in both dry and wet tests for loads up to 4,300 psi (302 kg/cm2) long term continuous operation, and short-term operation up to 8,000 psi (562 kg/cm2).

- Miter Gate Pintle Bearing Assemblies (Ball & Socket)

- Miter Gate Linkage Spherical Plain Bearings & Bushings

- Vertical Lift Gate Roller Wheel Assemblies

- Floating Mooring Bitt Bushings

- Wicket Gate Stem Bushings

- Wicket Gate Linkage Bushings

Location(s)

Locations (click on Directions):

Santa Fe Springs, California

13141 Molette Street, Santa Fe Springs, CA 90670Info@RBCBearings.com Phone: (714) 841-3007

Fax: (714) 841-3507