Industrial Tectonics Bearings Corp.

Contact Us

Send us a message

Note: Messages will be sent to Industrial Tectonics Bearings Corp. only

About Industrial Tectonics Bearings Corp.

Industrial Tectonics Bearing, or commonly known as ITB, was founded in 1955 and became part of the RBC Bearings family in 1990. The ITB manufacturing facility is located in Rancho Dominguez, California. ITB specializes in producing custom and specialty designs for our customers. The ITB facility is proficient in manufacturing a wide variety of products and sizes. ITB’s primary competency is high precision ball bearings. ITB also has a thin section ball bearing catalog offering that is suitable for Aerospace, Semiconductor, and Industrial applications up to 40 inches in diameter.

Industrial Tectonics Bearing, or commonly known as ITB, was founded in 1955 and became part of the RBC Bearings family in 1990. The ITB manufacturing facility is located in Rancho Dominguez, California. ITB specializes in producing custom and specialty designs for our customers. The ITB facility is proficient in manufacturing a wide variety of products and sizes. ITB’s primary competency is high precision ball bearings. ITB also has a thin section ball bearing catalog offering that is suitable for Aerospace, Semiconductor, and Industrial applications up to 40 inches in diameter.

ITB has a diverse manufacturing background that allows us to produce Roller Bearings, Needle Bearings, Cylindrical Roller Bearings, Ball Roller Bearings, Hourglass Roller Bearings, Complex Assemblies, and Specialty Products. Our manufacturing capabilities include heat-treating, hard turning, grinding, and super finishing. ITB’s manufacturing expertise coupled with our commitment to quality allow us to excel in a wide variety of end markets. At ITB, we are committed to deliver customer solutions that meet or exceed their needs, and provide world-class service while doing so!

Products

Thin Section Bearings, Industrial Tectonics Bearings Corp.

Thin section ball bearings are generally used in applications with space, weight, and load constraints. Typical applications are listed below:

|

|

Advantages of RBC Bearings thin section ball bearings are:

|

|

Standard cross sections range from 3/16� to 1� inch. Bore sizes can go up to 40 inches. Stainless steel and other materials are available depending on application need. Seals are available on all sizes and standard cross sections. Super duplex configurations give added rigidity and can also be applied to all sizes.

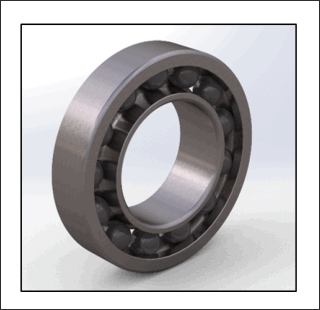

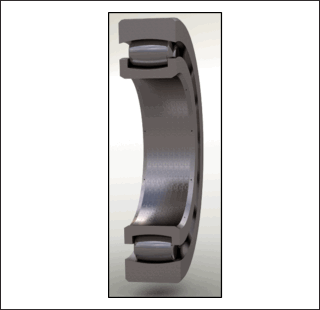

Roller Bearings, Industrial Tectonics Bearings Corp.

Compared to ball bearings, roller bearings have a higher load carrying capability due to line contact vs point contact. Roller bearings are optimized with large diameter rollers that allow for high speed applications. The motion of the races forces the elements inside to roll with very little rolling resistance.

Applications are listed below:

- Gear Boxes

- Landing Gear

- Trailer Wheels

- High Load Trucks

- Available in a wide variety of sizes

- Friction stability and energy expenditure are small

- Increased radial load capability

- Higher precision

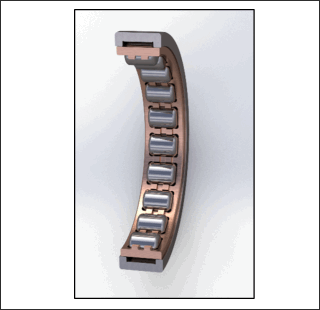

Needle Bearings, Industrial Tectonics Bearings Corp.

Needle Bearings are primarily used in vehicle components. They are of the smallest and lightest cross section in the roller bearing family. Needle bearings are a line contact bearing. They are designed to be light weight wile carrying heavy loads in oscillation.

Applications are listed below:

- Helicopter rotors transmissions

- Marine crankshafts

- Connecting rods

- Gear pumps

- Oil field pumping shafts

- Mud pumps

- Higher load capability than a single ball row or roller bearings of comparable OD.

- Integrated Can accommodate a larger diameter, more rigid shaft valves

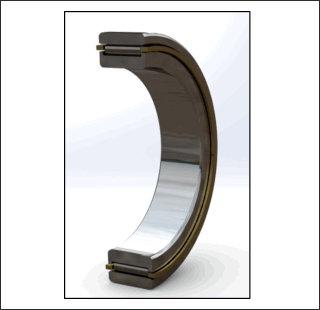

Hourglass Roller Bearings, Industrial Tectonics Bearings Corp.

Hourglass bearings are great for high load applications. This is due to the line contact that helps spread the load through the race way. These are also optimal for shaft misalignment.

Applications are listed below:

- Aircraft Flap System Actuator

- Fin Actuator

Advantages:

- Shaft misalignment

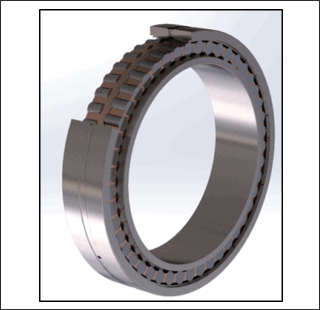

Spherical Roller Bearings, Industrial Tectonics Bearings Corp.

Spherical Roller Bearings are great for high load applications. This is due to the line contact that helps spread the load through the race way. These are also optimal for housing misalignment.

Applications are listed below:

- Aircraft Flap System Actuator

- Fin Actuator

- Housing misalignment

Location(s)

Locations (click on Directions):

Rancho Dominguez, California

18301 South Santa Fe Avenue, Rancho Dominguez, CA 90221ITBSales@RBCBearings.com Phone: (310) 537-3750

Fax: (310) 537-2909