RBC Transport Dynamics

Contact Us

Send us a message

Note: Messages will be sent to RBC Transport Dynamics only

About RBC Transport Dynamics

RBC Transport Dynamics (TDC) was founded in 1955 and is located in Santa Ana, CA. RBC Transport Dynamics is recognized as the World Leader in self-lubricating liner systems™. TDC was the original inventor of the self-lubricating lined spherical bearing, with the first application developed in 1957 for the Chevrolet Corvette suspension joint. Boeing later adopted this newly developed self-lubricating liner technology, and soon it was used extensively throughout the aerospace industry. TDC designs and manufactures a full line of plain bearings, rod ends, journal bearings (bushings), spherical bearings, links, and specialty assemblies.

RBC Transport Dynamics (TDC) was founded in 1955 and is located in Santa Ana, CA. RBC Transport Dynamics is recognized as the World Leader in self-lubricating liner systems™. TDC was the original inventor of the self-lubricating lined spherical bearing, with the first application developed in 1957 for the Chevrolet Corvette suspension joint. Boeing later adopted this newly developed self-lubricating liner technology, and soon it was used extensively throughout the aerospace industry. TDC designs and manufactures a full line of plain bearings, rod ends, journal bearings (bushings), spherical bearings, links, and specialty assemblies.

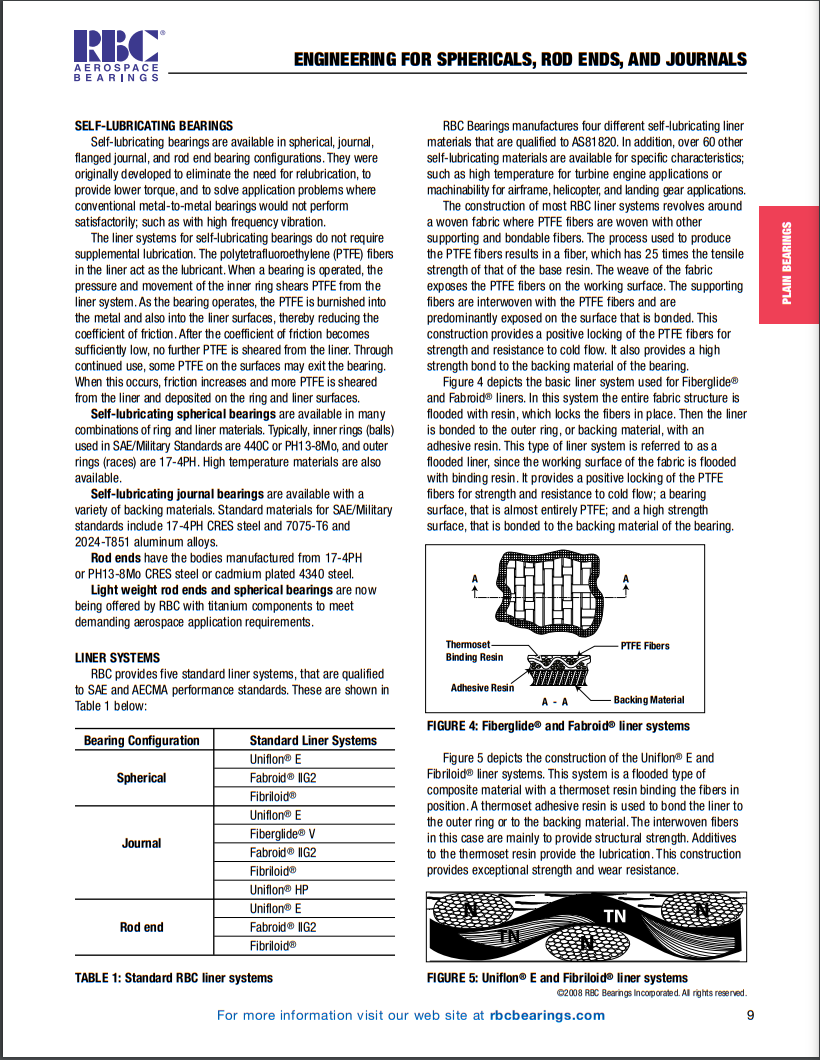

Plain bearings are primarily offered with our proprietary PTFE self-lubricating liner systems, although metal-to-metal options are also available. Transport Dynamics offers over 50 different proprietary self-lubricating liner systems. The correct liner system is selected based upon the load, wear, and temperature conditions in the application. These self-lubricating liners include TDC’s Fibriloid® liner which is universally recognized as the Gold Standard for self-lubricating liner systems. A TDC liner can be bonded to almost any metallic substrate to provide a fretting buffer as part of TDC’s “Bond Only” service to our customers. Additionally, TDC liner performance can be enhanced using hard, smooth coatings that can be applied to mating bearing surfaces. For highly loaded applications the Fibriloid® liner which is SAE AS81820 and AS81934 Type A (100,000 cycles) approved is the preferred standard. The proprietary Fabroid®X liner system is the most widely specified self-lubricating liner for high temperature applications (in excess of 600°F).

TDC manufactures plain bearings in conventional swaged outer race configurations, or as load slot entry configurations. The aerospace grade materials used include 440C, 17-4PH, 15-5PH, PH13-8Mo, Stellite®, Inconel®, titanium and aluminum. Other material options are readily available.

The breadth of applications serviced includes aircraft gas turbine engines, commercial and military aircraft, helicopter, landing gear, space vehicles, alternative energy (ground power & wind) and military/defense, including hypersonic missiles. TDC is considered to be an Engineered Solutions Provider with extensive applications engineering and testing support.

The core competencies of TDC include milling, grinding, swaging, bonding, special processes (passivation, cadmium plate, dry film lubricant, High Velocity Oxy Fuel (HVOF) coatings), staking and extensive non-destructive testing (NDT). TDC is a multi-year Boeing Performance Excellence Award (BPEA) winning supplier to Boeing.

Trademark Information

Inconel® is registered trademark of Inco Alloys International Inc., Corp. of Huntington West Virginia

Stellite® is a registered trademark of Kennametal Inc. of Latrobe, Pennsylvania

Products

Catalogs and Brochures

MS Spherical Bearings, Transport Dynamics

Self-Lubricating Spherical Bearings qualified to AS81820.

There are 4 part number series:

- MS14101 (Narrow Grooved)

- MS14102 (Wide Chamfered)

- MS14103 (Wide Grooved)

- MS14104 (Narrow Chamfered)

The "AS" prefix Procurement Specification are direct equivalents.

Typical Applications:

- General Purpose (Broad Range)

- Contacting Lip Seals offer positive retention of lubrication and exclusion of contaminants.

- Aircraft – flight controls, landing gear, aircraft doors, engines

- Industrial

- Maintenance Free – no intervening maintenance (re-lubrication).

- Also available Type A approved (100,000 cycles) featuring the proprietary Fibriloid® liner which is recognized as the Gold Standard in the aerospace industry.

- Temperature Range: -65°F to +325°F

- Corrosion Resistant

Spherical Plain Bearings, Transport Dynamics

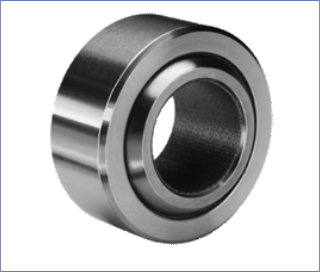

We offer a full line of Standard and Custom Spherical Plain Bearings both in Metal-to-Metal and Self-Lubricating versions. Configurations include Swaged, Loader Slot, Split Ball, and High Misalignment designs.

Spherical Plain Bearings are best suited for high load, pivoting or angular misalignment and low velocity oscillations in applications such as:

- Hydraulic Actuator Rod Ends

- Steering Linkage and Suspensions

- Articulated Joints

- Heavy Equipment and other Severe Duty applications

- Supports higher loads than rolling element bearings

- Smaller size for the same performance as compared to rolling element bearings

-

Maintenance-free option

- World Leader in Self-Lubricating Liner Systems™

Links and Rod Ends, Transport Dynamics

We offer a full line of Custom Designed Links and Rod End Bearings both in Metal-to-Metal and Self-Lubricating versions. Configurations include Solid Links, Welded Links, Turn-Buckle Rod End Assemblies and Rod End Bearings with Spherical Bearing Cartridges.

Transport Dynamics Links and Rod End Bearings are best suited for high load, pivoting or angular misalignment and low velocity oscillations in applications such as:

- High Temperature or High Loaded Linkages

- Hard to access Articulated Joints

- Steering or Suspension and other Severe Duty uses

Benefits Include:

- Maintenance-free versions eliminate the need to re-lubricate and removes the need for lubrication fittings

- Corrosion Resistant

- High Strength and Ductility

- High Temperature Capability

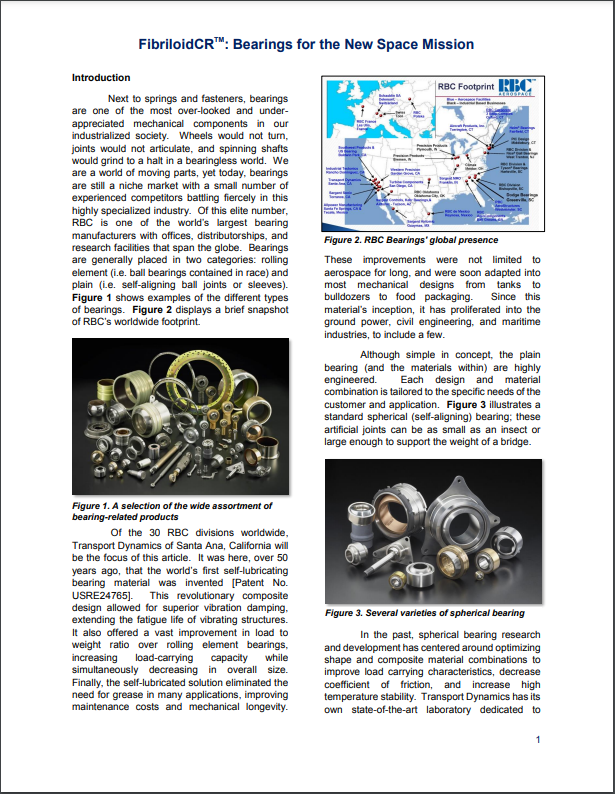

FibriloidCR™ Series, Plain Bearings for Space Applications

The FibriloidCR™ series of cryogenic rated bearings and rod ends features the proprietary Fibriloid® liner, which is widely recognized as the most versatile and best performing self-lubricating liner in the aerospace industry. The FibriloidCR™ series has been tested and flight proven to support rigorous application requirements assuring optimal performance in space environments

Transport Dynamics FibriloidCR™ series is best suited for high load, pivoting or angular misalignment operation at low oscillation in Space Launch Vehicle and Satellite applications:

-

Propulsion

- Booster Engines

- Turbo Pumps

- Actuators

- Fuel Tanks

- Landing Gear

- Maintenance-Free – no intervening maintenance required (re-lubrication).

- Superior wear performance

- Low coefficient of friction at operating temperature

- Wide temperature range (°F): -320° (Cryogenic Range) to +450°

For more information on the FibriloidCR™ series, please explore our catalog, white paper and promotional flyer attached below.

FibriloidCR™ Series

Cryogenic Bearings Catalog |

FibriloidCR™ Series

Bearings for the New Space Mission |

FibriloidCR™ Series

Plain Bearings for Space Applications |

RBC® Aerospace Wear Strips: X-Guard™ | How To Prevent Fretting, Corrosion & Extend Materials Life Span

Contact wearstrips@rbcbearings.com today to eliminate fretting and corrosion from your application!

Additonal Information

Location(s)

Locations (click on Directions):

Santa Ana, California

3131 W. Segerstrom Ave. Santa Ana, CA 92704-9998, Santa Ana, CA 92704-9998TDCRFQ@RBCBearings.com Phone: (714) 546-3131

Fax: (714) 545-9885

_Thumbnail.PNG)