Kahr Bearing

Contact Us

Send us a message

Note: Messages will be sent to Kahr® Bearing only

About Kahr® Bearing

RBC Kahr Bearing operates out of RBC - Sargent Aerospace and Defense’s facility in Tucson, AZ. The Tucson facility houses Kahr Bearing’s sales, design, test, R&D and manufacturing operations teams. Vertical integration allows Kahr the flexibility to design new bearings from the self-lubricating liner on up, and then manufacture, test, and qualify them on-site. The Tucson facility is AS9100D, and ISO accredited. In addition, Sargent Controls and Aerospace/Kahr Bearing operates an FAA Part 145 (S1CR155N) and EASA (EASA.145.4850) Repair Station for the repair and overhaul of a wide variety of self-lubricating bearing system components and specializes in landing gear self-lubricating bearing systems.

RBC Kahr Bearing operates out of RBC - Sargent Aerospace and Defense’s facility in Tucson, AZ. The Tucson facility houses Kahr Bearing’s sales, design, test, R&D and manufacturing operations teams. Vertical integration allows Kahr the flexibility to design new bearings from the self-lubricating liner on up, and then manufacture, test, and qualify them on-site. The Tucson facility is AS9100D, and ISO accredited. In addition, Sargent Controls and Aerospace/Kahr Bearing operates an FAA Part 145 (S1CR155N) and EASA (EASA.145.4850) Repair Station for the repair and overhaul of a wide variety of self-lubricating bearing system components and specializes in landing gear self-lubricating bearing systems.

Kahr Bearing was one of the first companies to develop and produce self-lubricated bearings. For nearly 70 years, Kahr has built a reputation as an engineered solutions provider, being viewed by many customers as an extension of their own engineering department.

Kahr’s products are used on military and commercial helicopters and aircraft, landing gear, military vehicles/tanks, submarines, satellites and the international space station. From the F-22 fighter aircraft to the V-22 tiltrotor, from submarines and rail applications, to 21st century development programs, Kahr Bearing takes pride in solving our customers’ most difficult design challenges with a drive for new technology backed by a long history of customer focus and support.

Kahr has developed proprietary self-lubricating liner systems that are among the best performing bearing liner systems in the world. Kahr offers over 14 different self-lubricating liner systems including the Kahr-Lon® liner system.

Kahr manufactures a full line of plain bearings including journal bearings (bushings), spherical bearings, rod ends, linkages, and specialty assemblies. Spherical bearings include conventional swaged outer race, load slot entry, Kahr-Kaptor®, and split ball styles. The aerospace grade materials used includes; 440C, 17-4PH, 15-5PH, PH13-8Mo, Stellite®, Inconel®, titanium, and aluminum. Other material options are readily available.

Experts in the Industry

Starting in the concept phase, Kahr partners with our customers to ensure that the end product is a success, and then stands behind the designs with outstanding customer service and product support.Kahr Bearing is proud to be recognized as a 2019 Elite Supplier to the Lockheed Martin Rotary Mission Systems Group, and is the only bearing manufacturer to be qualified and QPL listed to the rigorous standards ofAS81819 high speed oscillation specification which is intended for helicopter main and tail rotor bearing applications. We invite you to contact Kahr Bearing for more information about our full range of self-lubricatedliner technologies.We love a challenge and are up to the task.

Trademark Information

Inconel® is registered trademark of Inco Alloys International Inc., Corp. of Huntington West Virginia

Stellite® is a registered trademark of Kennametal Inc. of Latrobe, Pennsylvania

Please visit the Kahr Bearing website: www.sargentaerospace.com

Products

Wear Strips, Kahr Bearing

Wear Strips are composite liners that can be applied to prevent incidental damage to mating components. Wear Strips are sold in standard sheet sizes or custom shapes and are available with peel ply and peel-and-stick backings to allow for ultimate flexibility as each application requires.

Wear Strips are typically applied as follows:

- Bump Pads

- Cover Panel Wear Protection

- Sliding Groove Protection

-

Under varying conditions such as:

- High contamination

- Edge Loading

- Adverse wear surfaces

- Improved wear life of mating joints over metal-to-metal contacts

- Protecting expensive components from incidental damage, increasing service life

- Ease of installation both at the OEM and as an aftermarket addition

Fretting Buffers, Kahr Bearing

Fretting Buffers are composite liners that, when applied between static components, protect against fretting, galling or galvanic corrosion damage to the mating surfaces.

Fretting Buffers are typically applied on the static interface surfaces of bearings such as:

- Landing Gear Shock Strut Bearings

- Steering Collars/Torque Tubes

- Axle Retainers/Tow Fittings

- Actuation Bearings

- Flight Control Bearings

- Support Bearings

- Airframe Bearings

- Protection from fretting, galling and galvanic corrosion

- Minimizing or eliminating housing damage during bearing removal

Kaptor® Bearings, Kahr Bearing

Kaptor® Bearings are metal-to-metal or self-lubricating, low-friction bearings incorporating a threaded retainer ring for installation and replacement where accessibility for staking or high thrust loads prevent traditional bearing retention methods.

Kaptor® Bearings are typically installed as follows:

- Trunnion Bearings

- Wing Attachment Bearings

- Spindle Bearings

- MS Standard Replacement Bearings

- Ease of installation and removal

- Ability to handle high thrust loads

- Dimensional equivalence to MS standard bearings allowing direct replacement

RBC® Aerospace X-Guard™ | How To Prevent Fretting, Corrosion & Extend Materials Life Span

Contact wearstrips@rbcbearings.com today to eliminate fretting and corrosion from your application!

Additonal Information

MRO & PTFE Liner Application |

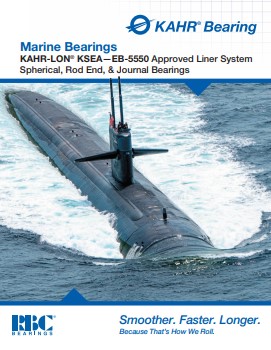

KAHR-LON® K-SEA PTFE Self-Lubricating Submergible Liner System |

KAHR-LON® K-SEA Marine Bearings Catalog |

X-Guard™ Wear Strips |

Location(s)

Locations (click on Directions):

Tucson, Arizona

5675 West Burlingame Road, Tucson, AZ 85743Kahr@RBCBearings.com Phone: (520) 744-1000

Toll Free: (800) 230-0359

Fax: (520) 744-9494