RBC Aircraft Products, Inc.

Contact Us

Send us a message

Note: Messages will be sent to RBC Aircraft Products, Inc. only

About RBC Aircraft Products, Inc.

RBC Aircraft Products Inc. (API) originated as part of the Torrington Company dating back to the 1890’s, and has a long history as being the market leader in Airframe Control Ball and Needle Roller Bearings. API also offers Precision Ball and Roller bearings as well as Hourglass Roller Bearings.

RBC Aircraft Products Inc. (API) originated as part of the Torrington Company dating back to the 1890’s, and has a long history as being the market leader in Airframe Control Ball and Needle Roller Bearings. API also offers Precision Ball and Roller bearings as well as Hourglass Roller Bearings.

In 2003, API was acquired by RBC Bearings, a leader in the world of highly engineering aerospace bearing products. The API facility has remained in Torrington, Connecticut, and continues to manufacture the original Torrington/Fafnir Airframe product lines.

API specializes in new bearing technologies providing the market with specialty corrosion resistant CREN steel, and has full in-house bearing testing capabilities for the most demanding applications. Core competencies include Precision Grinding, Zinc Nickel Plating, Non-Destructive Testing (NDT), and Clean Room Assembly/Inspection.

API is a multi-year Boeing Performance Excellence Award (BPEA) winning supplier.

Products

Airframe Ball Bearings, API Division

Airframe Ball Bearings are available in sizes from 3/16” ID to 6” OD. They have many Industrial uses beyond aircraft applications due to their high load carrying capacity and corrosion resistance.

Primary applications include:

- Commercial and military aircraft flight control applications such as flap and slat actuation systems

- Industrial Automation/Robotics

- Packaging Equipment

- High reliability applications such as Industrial Circuit Breakers

- Maximizing capacity within a compact design

- Providing low starting and running torque

- Being lubed for life reducing maintenance requirements and cost

- Providing exceptional performance in oscillatory applications

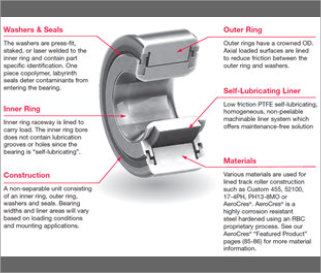

Self-Lubricating Lined Track Rollers, API Division

Self-Lubricating Lined Track Rollers are designed for applications where the bearing acts as a roller on a flat surface such as a track or cam. Track Rollers are supplied as either yoke style (for mounting on a shaft) or stud type with an integral threaded stud. Lined Track Rollers utilize a high tech self-lubricating liner system to eliminate the need for lubrication in the bearing.

Like their needle roller equivalents, these products are commonly used in:

- Flight control application such as flaps and slats

- Can making/high speed processing equipment

- Food & Beverage applications where corrosion resistance is essential

- Applications where re-lubrication is a challenge.

- Offering a low friction Uniflon® HPA self-lubricating, non-peelable, machinable liner system on the inner ring raceway and axial loaded thrust surfaces

- Providing a bearing that is “Maintenance Free” for the life of the bearing.

Needle Roller Track Rollers, API Division

Track Rollers are designed for applications where the bearing acts as a roller on a flat surface such as a track or cam. Track Rollers are supplied as either yoke style (for mounting on a shaft) or stud type with an integral threaded stud.

These products are commonly used in:

- Flight control application such as flaps and slats

- Can making/high speed processing equipment

- Food & Beverage applications where corrosion resistance is essential

- Providing consistent low friction levels under varying conditions. Coefficient of Friction ~ 0.005 to 0.02

- Utilizing Combination Seal/Thrust Washers to retain lubricant and exclude contaminants.

- Providing exceptional environmental and chemical resistance.

- Offering outstanding corrosion resistance when manufactured from Aerocres® CREN material.

Trademark Information

Inconel® is registered trademark of Inco Alloys International Inc., Corp. of Huntington West Virginia

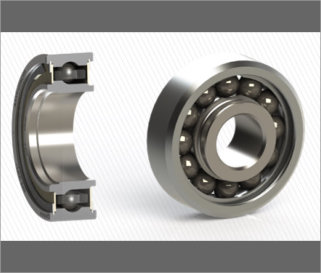

Radial Ball Bearings, API Division

API Division supplies a wide variety of custom designed solutions for some of the most demanding applications on the planet and beyond.

Capabilities include:

- Special Configurations: Angular Contact, 4-point Angular Contact, Duplex and Multi-Row

- Special Materials, Plating, Coatings, Lubricants for Corrosion Resistance and Performance

- High Precision Levels – Up to ABEC 7+

- Designs for Low Torque, Low Noise, High Temperature Applications

- High speed gear boxes

- Semi-conductor manufacturing equipment

- Can making/high-speed processing equipment

- Aerospace, Defense, Satellite applications

Roller Bearings, API Division

API produces several types of roller bearings:

- Hourglass Roller Bearings in single and double row styles

- Barrel Roller Bearings in single and double row styles

- Size ranges from ½” bore to 10” OD

These bearings improve performance by:

- Carrying Heavy Radial and Axial Loads

- Handling High Misalignment, both static and dynamic

- Providing High Stiffness under load

- Allowing Close Control of Free Play (Clearance)

- Available in Sealed Versions to retain lubricant and exclude contaminants

Location(s)

Locations (click on Directions):

Torrington, Connecticut

2788 Winsted Road, Torrington, CT 06790API@RBCBearings.com Phone: (860) 626-7800

Fax: (860) 626-7886