RBC Turbine Components

About RBC Turbine Components

RBC Turbine Components (TCI) is an FAA part 145 and EASA certified repair station specializing in maintenance, repair, and overhaul of assemblies used in military,

and commercial, flight engines and auxiliary power units (APUs). TCI also produces cold and hot section assemblies for APU and flight engines (new manufacture) for major gas turbine engine OEM’s.

TCI specializes in combustion liner assemblies, combustor cases, and hot section vacuum furnace brazed assemblies.

RBC Turbine Components (TCI) is an FAA part 145 and EASA certified repair station specializing in maintenance, repair, and overhaul of assemblies used in military,

and commercial, flight engines and auxiliary power units (APUs). TCI also produces cold and hot section assemblies for APU and flight engines (new manufacture) for major gas turbine engine OEM’s.

TCI specializes in combustion liner assemblies, combustor cases, and hot section vacuum furnace brazed assemblies.

TCI has a wide selection of processing services including robotic thermal spray coating (plasma spray and High Velocity Oxy Fuel (HVOF)), vacuum furnace diffusion brazing and heat treating, welding (TIG, micro-plasma arc, resistance spot roll and seam, electron beam), CNC turning and 5-axis milling.

TCI is ISO9001 and AS9100 Rev. D accredited, and is NADCAP certified for welding, heat treating, and non-destructive testing (NDT).

Please visit the RBC Turbine Components website: www.rbcturbinecomponents.com/

Products

Reduction Gearbox Overhaul, RBC Turbine Components

Complete overhaul of both reduction gearbox (RGB) housings for all PT6 engine variants. All processes performed in accordance with latest Pratt & Whitney Overhaul Manuals.

Repair Certifications:

- EASA

- FAA

- Full dimensional & fluorescent inspection

- Full dimensional restoration

- Detail replacement including inner bearing sleeve

- Complete coating restoration – inner and outer

- Complete restoration of anti-friction compound

- FAA 8130-3 Certification

3/4 Bearing Housing Overhaul, RBC Turbine Components

Repair and overhaul of 3/4 bearing housing for all PT6 engine variants. All processes performed in accordance with latest Pratt & Whitney Overhaul Manuals. Additional extended repair processes granted to TCI to allow flange replacement.

Repair Certifications:

- EASA

- FAA

- Full dimensional & fluorescent penetrant inspection

- Full dimensional restoration

- Bolt hole flange restoration & stud replacements

- Corrosion blend removal as required

- Complete coating restoration

- Housing flange replacement

- FAA 8130-3 Certification

Compressor Stator Overhaul, RBC Turbine Components

Repair and overhaul of compressor stator stages for all PT6 engine variants. All processes performed in accordance with latest Pratt & Whitney Overhaul Manuals.

Repair Certifications:

- EASA

- FAA

- Full dimensional & fluorescent penetrant inspection

- Corrosion blend removal as required

- Complete coating restoration

- Coming Soon: Vane tip replacement

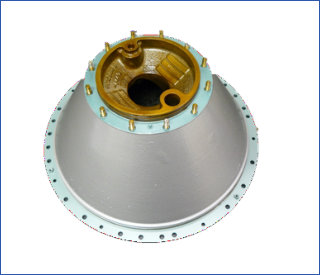

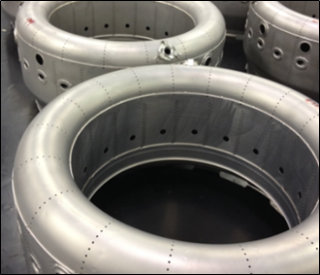

Combustion Liner Repair and Overhaul, RBC Turbine Components

Repair and overhaul of combustion liner assemblies for auxiliary power units (APUs) and gas turbine flight engines.

Repair Certifications:

- EASA

- FAA

- Oxidation layer removal

- Full dimensional restoration

- Detail replacement (grommets, ignitor bosses, etc.)

- Inner, outer liner, or dome replacement

- Manufacture and replace cooling strips

- Vacuum furnace brazing for replacement components

- Non destructive testing (NDT)

- FAA 8130-3 Certification

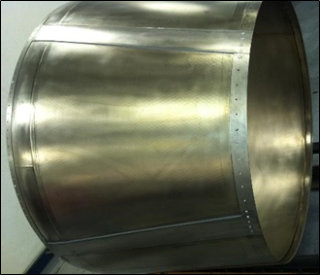

Exhaust Nozzle Repair and Overhaul, RBC Turbine Component

Repair and overhaul of outer and inner exhaust nozzles. Specialize in PW4000 exhaust nozzles (all models)

Repair Certifications:

- EASA

- FAA

- Rivet hole crack restoration

- Patch repair cracks and deformation

- Fusion weld crack repair

- Correct skin delamination

- Restoration of T-Ring (inner liner)

- Application of dry film lube (inner liner)

- Application of tungsten carbide coating

- Remove & replace rub strips / rub pads

- Heat treat nozzle

- Restore saddle

- Dimensional inspection and restoration

- NDT inspection

- FAA 8130-3 Certification

Combustion Liner Repair and Overhaul, RBC Turbine Component

RBC Bearings has been the pioneer in spherical plain bearing technology since inventing the fractured outer race design many years ago. Since that time, RBC Bearings has continued to introduce industry leading innovations. RBC’s spherical plain bearings are available in both inch and metric sizes, sealed and non-sealed, with inner dimensions ranging from ½ to 12 inch and 12 to 320 millimeters.

Repair Certifications:

- EASA

- FAA

- Oxidation layer removal

- Full dimensional restoration

- Detail replacement (grommets, ignitor bosses, etc.)

- Inner, outer liner, or dome replacement

- Manufacture and replace cooling strips

- Vacuum furnace brazing for replacement components

- Non destructive testing (NDT)

- FAA 8130-3 Certification

Location(s)

Locations (click on Directions):

San Diego, California

8985 Crestmar Pt, San Diego, CA 92121=b!isfg>#nbjmup;UDJTbmftASCDCfbsjoht/dpn#?UDJTbmftASCDCfbsjoht/dpn=0b? Phone: (858) 678-8568

Fax: (858) 678-0703